pickle and passivate stainless steel

The first chemical process mentioned in A380 is descaling. Ad Browse discover thousands of brands.

Pickling Passivation Cleaning Chemicals For Stainless Steel With Vk Chemicals Asma380 Youtube

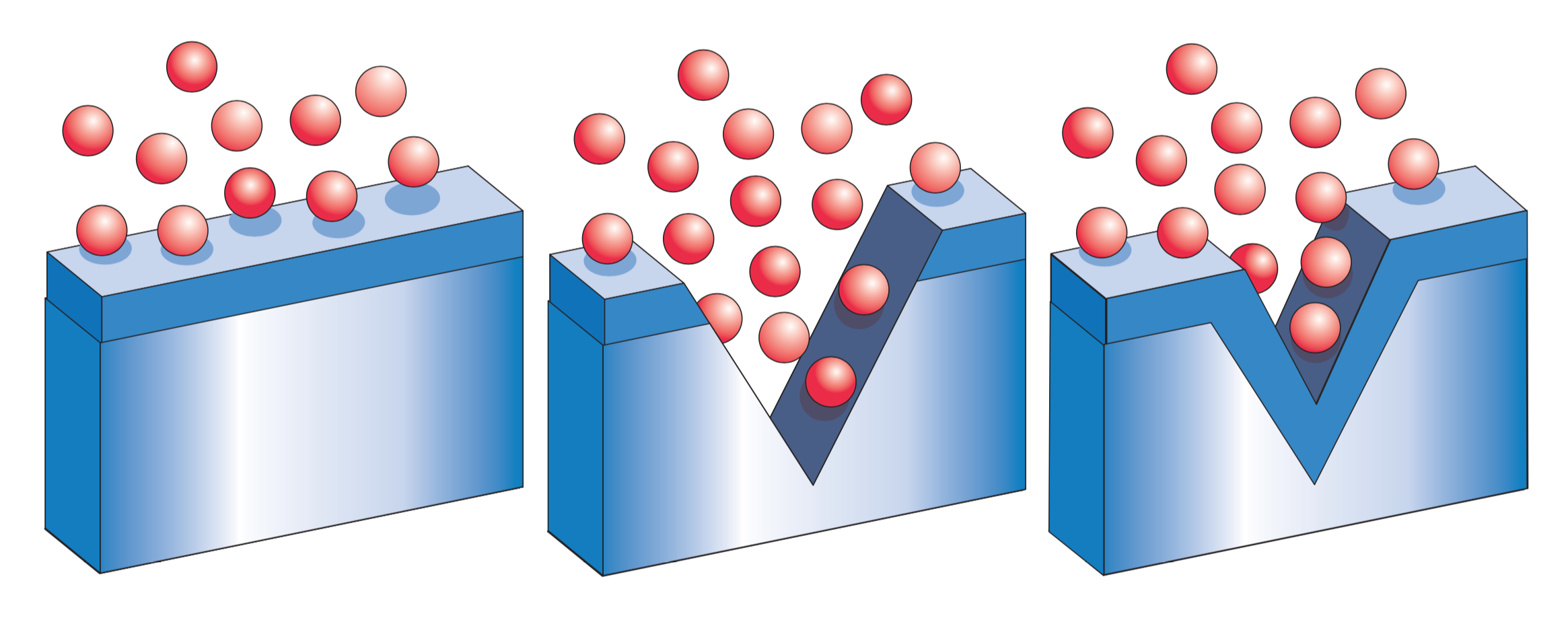

Descaling removes tightly bound metal oxides adhered to the stainless steel surface.

. The procedure of passivating stainless steel effectively removes cost-free iron and also international products from the parts surface area leaving the component clean and more deterioration resistant. Pickling and passivation are both acid treatments and neither will remove grease or oil. We have the solutions.

Our chemical process of passivation removes exogenous iron at the stainless steel surface for the sake of enhancing the corrosion resistance of the already existing chemically inactive oxide layer. Pickling and passivation treatments may be necessaryto fullyprepare machined or fabricated stainless steel surfaces for their intended service conditions. Pickling and Passivation are chemical processes used in the metal industry to protect metals from corrosion.

Unlike pickling the passivation process does not remove any metal. Acid pickling may also provide sufficient passivation depending on its specific application. However descaling may be necessary for passivation to be effective.

The wide range of concentrations and exposure times are described in ASTM A380 Standard Practice for Cleaning Descaling and Passivation of Stainless Steel Parts Equipment and Systems. Traditionally The most economical and convenient surface finish for stainless steel castings is acid pickling. Pickling and passivation are often used together to remove contaminates and oxidation improving corrosion resistance and extending the life and overall value of.

Most of our new customers are surprised to find out that stainless steel pickling also accomplishes passivation. After a comprehensive pickling and passivation for stainless steel pipe and fittings all kinds of oil rust oxide skin welding spots and other dirt can be removed. If the fabrication is dirty it may be necessary to use a detergent or alkaline clean before pickling or.

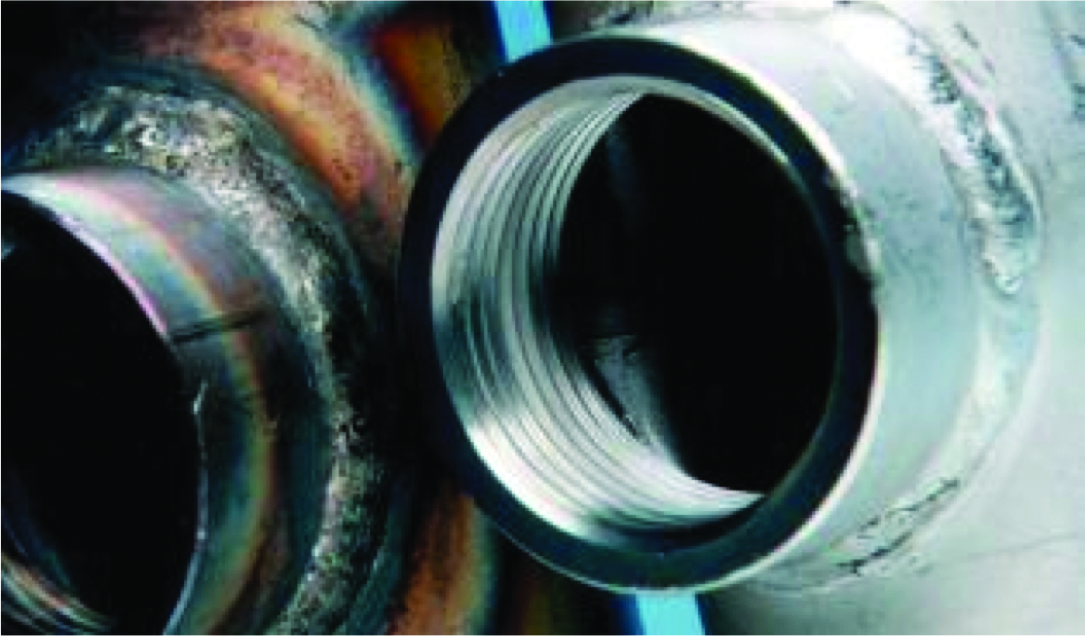

PICKLING AND PASSIVATING STAINLESS STEEL Light scaling left on weld. It sounds like your parts are being etched by the process. There is no reason for this to happen even with standard 304 AISI 304 stainless steel if the pickling and passivation baths are correct.

And the surface of stainless steel will. Ad Remove rust and passivate stainless steel with Citrisurf. Ad Regal Offers Used Reconditioned Industrial Pickle Cutters.

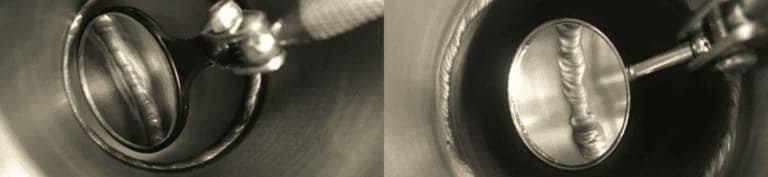

There are a number of stainless steel surface treatments meant to develop or enhance the steels passive layer. Pickling uses a mixture of nitric and hydrofluoric HF acids. This is our one-step process which removes heat tint and weld scale while simultaneously passivating the surface of the parts being processed.

304L is low carbon and may be better in the bath that is being used of course but it depends on the application of the final part whether you. The most common application for stainless steel pickling is picklepassivate by Delstar. Pickling and passivation are two forms of chemical metal finishing that provide protective properties to metal especially against rust.

Free shipping on qualified orders. Contact Us To Learn More. Before and after pickling passivating The performance of stainless steel is achieved by special alloy composition in which chromium plays a leading role.

Stainless steel pickling passivation paste has been widely used in China and has a series of products. 2 According to the process requirements the pipeline to be pickled and passivated must be checked and qualified. 3 Prepare the cleaning package and cleaning tracking table for the.

31 Preparations before pickling and passivation. Free easy returns on millions of items. 1 Complete the welding pressure release and non-destructive testing of pickling and passivation pipelines.

ASTM A380-17 details these three services in detail thoroughly addressing their acceptable methods for new stainless steel parts equipment and systems. Some acidic chemicals are used over the stainless steel to create a passive layer or to remove contaminants. What is Pickling and Passivation for Stainless Steel a Application.

The main components are nitric acid hydrofluoric acid corrosion inhibitor and viscous agent in a certain proportion. Pickling solution means to immerse the stainless steel casting in an acid solution for about 20-30 minutes to remove the surface rust then the casting surface has a dense passivation film. The chromium combines with the oxygen and forms an extremely thin and hard chrome-oxide film to protect the bottom part of the stainless steel.

Pickling and passivation both are chemical treatment processes used for surface treatment of stainless steel after welding or exposure to high temperature to clean. Passivation is a process that is separate from pickling which can be performed on its own or after pickling. Both pickling and passivation are widely used for stainless steel products.

Or in other terms pickling and passivation are the name of the two processes where the metal is submerged in a bathing liquid that removes imperfections and rust from the surface of metal. Los Angeles California area pickling and passivation. Those processes are descaling pickling and passivation.

This passive layer is just that passive meaning that it inhibits reactivity preventing the occurrence of reactions such as oxidation also known as rust formation. The standard does not cover decontamination. Read customer reviews find best sellers.

If stainless parts are contaminated with grease or oil then a cleaning operation prior to acid treatment should be carried out. Pickling solution for stainless steel castings. We Continue to Have an In-Depth Selection of Used Refurbished Pickle Cutters.

Instead the surface of the stainless steel is treated with an oxidizing acid to dissolve carbon steel sulfide inclusions and remove iron and other surface contaminants from the stainless. Pickling and Passivation are chemical treatments applied to the surface of stainless steel to remove contaminants and assist the formation of a continuous chromium-oxide passive film.

New Pickling And Passivation Baths Cb Stainlesscb Stainless

Principle And Method Of Pickling And Passivating Stainless Steel

Pickling And Passivation On Stainless Steel Youtube

Passivazione Dell Acciaio Inossidabile Nitty Gritty

Pickling And Passivating Of Metals Vecom Group

Pickling And Passivation Of Stainless Steel Www Materialwelding Com

Passivating Hotsell 60 Off Www Centrehara Com

Stainless Steel Pickling Descaling Services Delstar Metal Finishing Inc

Stainless Steel Passivation For Enhanced Durability And Versatility

Pickling And Passivating Stainless Steel Safe Food Factory

Pickling And Passivation Of Stainless Steel Pipes

Stainless Steel Passivation For Enhanced Durability And Versatility

Passivazione Dell Acciaio Inossidabile Nitty Gritty

Inox Passivation Pickling Passivation Astm Asme

How To Pickle And Passivate Stainless Steel

Fsh Welding Canada Stainless Steel Pickling And Passivating Youtube